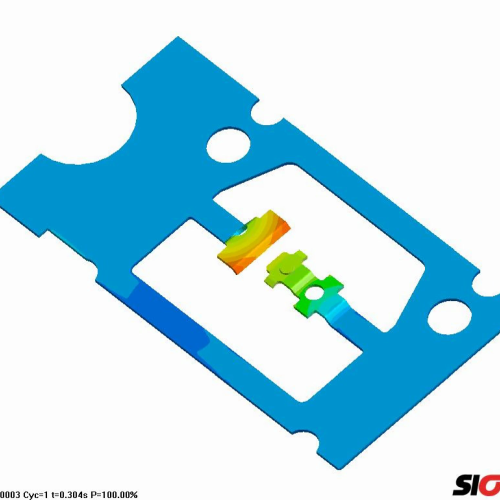

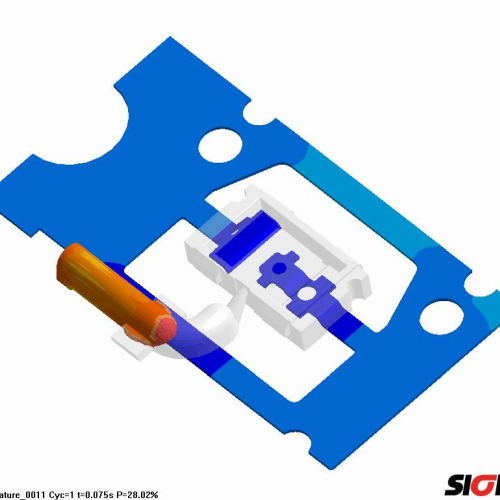

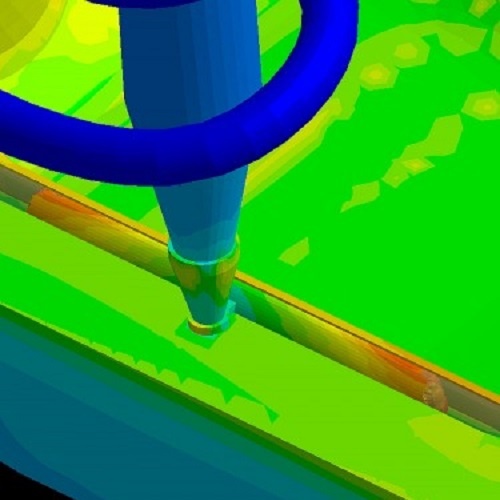

The application in the videos shows an insert that needed to be over-molded by a polymer. The thermal and mechanical behavior of the insert during the injection molding process needed to be predicted. A SIGMASOFT® Virtual Molding analysis was immediately able to indicate if the component would survive the planned injection molding process. Detailed information about the temperature, pressure and shear stress on the soldered joints was part of the solution given by SIGMASOFT®. Stress developing in the inserts due to the history of temperature, pressure, crystallization and shrinkage constraints during the whole process was readily available for design engineers. Areas prone to failure could be identified and counter measures were elaborated even before the mold was fabricated.

Exemplarily, the animations below show the overmolding of the metal insert and its corresponding deformation. Induced stresses cause the arms of the insert to warp and – under unfavorable conditions – even to generate a short circuit, turning the finished part to scrap. Physical modeling using real temperature dependent material properties allowed the engineers to reliably analyze the process. Knowing beforehand the probability of arm contact empowered the engineers to make effective design changes. Thus expensive experimental mold trials and iterations were saved.