The design and gating of rubber parts is normally based on experience. Sometimes, however, when confronted with a complete new part, the engineering team does not have any previous experience available, or despite the “best guess” the designed mold does not work as expected.

In these cases it is useful to be able to predict with high accuracy how the rubber melt will behave under certain conditions and if the part is going to have defects.

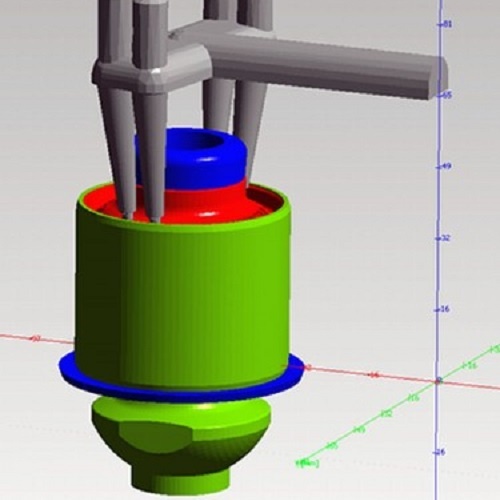

Integrating the most accurate flow and material models available, SIGMASOFT® Virtual Molding can predict the complex interaction between melt viscosity, heat transfer and curing degree of a molded rubber melt. In the first animation, the cavity filling in a rubber mold is presented. The temperature in the melt is registered in the colored scale. The differences in melt temperature obey differences in the melt behavior when flowing through different cross sections. The shear induces melt heating, cold spots in the mold can delay cycle time.

In the second animation, the melt front is presented. The regions where weld lines are formed are marked in color, and the intensity of these weld lines – the “danger” they represent for part performance – is signalized.

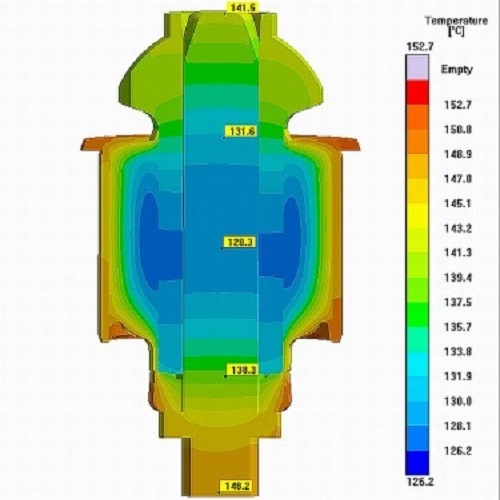

The curing degree of the mold part is displayed in Figure 1. Critical low-curing areas can be easily identified. In this part, after a cycle time of 99 seconds there are still regions where the curing degree is under 30%. These regions may cause undesired part shrinkage or sink marks, or they can produce part failure during service.