SIGMASOFT® Thermoplast

From the part idea to series production, you have to take a variety of decisions.

It's all about the details

and SIGMASOFT® Virtual Molding

supports you in your decisions.

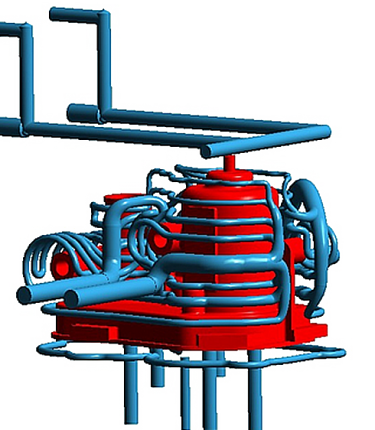

SIGMASOFT® stands for a holistic approach of the simulative injection molding process. With this principle, you can expand your project quickly from the calculation of a part, through initial tempering concepts, up to complete virtual mold configurations. Based on the real thermal properties of the 3D mold, SIGMASOFT® provides a reliable basis for decisions in the development process.

SIGMASOFT® VIRTUAL MOLDING SUPPORTS SOLVING COMPLEX CHALLENGES IN INJECTION MOLDING FROM DESIGN TO PROCESSING.

THAT’S WHAT YOU CAN EXPECT IN SIGMASOFT® Thermoplast:

- Easily predict filling, packing, and cooling behavior of thermoplastics

- Calculate fiber orientation

- Foresee crystallization behavior of semi-crystalline polymers

- Show deformation of mold cores and inserts during filling

- Calculate the part temperature outside the mold as well as temper processes

- Analyze shrinkage and warpage inside and outside the mold

- Realize multi-component injection molding

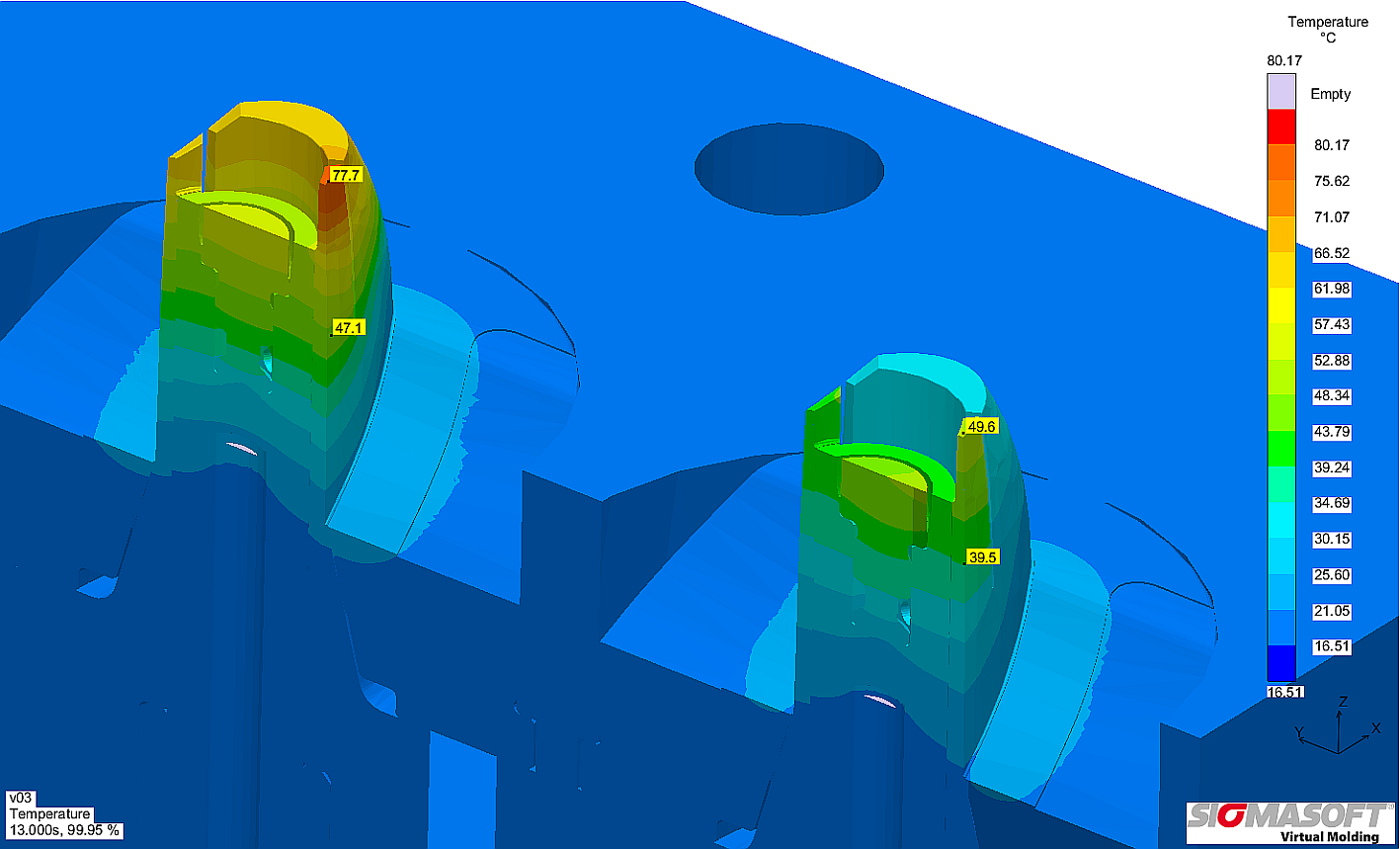

- Optimize tempering concepts in the mold

- Analyze energy efficiency

VIRTUAL MOLDING INSTEAD OF JUST SIMULATION:

THE MOLD MAKES THE DIFFERENCE!

Not only the behavior of the part but also the thermal behavior of the mold can be analyzed and optimized with SIGMASOFT® Thermoplast. You will accelerate the development process and achieve the desired part quality from the very first shot. Furthermore, you are able to start the virtual series production even before your mold is built.

Intelligent, automatic meshing algorithms allow you to mesh an entire mold in less than five minutes and mesh repairs of any kind belong to the past. Take a look inside the mold while it is running.

MAKE SIGMASOFT® YOUR TOOL AND...

... YOU WILL GET MORE OUT OF YOUR PROJECTS!

OUR IN-HOUSE DEVELOPMENT AND THE TEAM OF EXPERIENCED ENGINEERS IS YOUR SERVICE!

Successful injection molding simulation requires the direct contact between the users and a competent engineering team. Therefore, our solution service, our customer support as well as our application-oriented software developers work closely together with you for your success!

Get rid of your stress.

SIGMAstress prevents

shrinkage and warpage!

SIGMASOFT®

Thermoplast INFORMATION FOR YOU TO DOWNLOAD!

YOUR INSIGHT INTO OUR CASE STUDIES:

Casestudy

IMPROVE YOUR PART QUALITY CONTROLLING THE MOLD TEMPERATURE

Casestudy

SELECTING THE BEST TOOL ALLOY TO REDUCE MOLDING CYCLES

Casestudy

OVER-MOLDING SENSITIVE COMPONENTS: HOW TO AVOID COMPONENT DAMAGE