Virtual Thermoplastics - Understand the injection molding process in detail and predict it more precisely

The goal of predicting the injection molding process more accurately requires high-quality and precise material data, which is not always available in practice. In cooperation between DUFNER.MDT GmbH and SIGMA Engineering GmbH, a completely new database for simulation was being created.

Aachen, 12.10.2021 – SIGMA Engineering will give an insight into the world of Virtual Thermoplastics for the first time at Fakuma (October 12-16, 2021) in Friedrichshafen, Germany, on booth A5-5110. The injection molding process should not only be understood in the smallest detail, but also reliably and extremely precisely predicted. Comprehensive knowledge of the processed material optimizes every process and enables greater reliability.

The behavior of plastics in injection molding is complex and the influence of material properties on the injection molding process is very high. For a further increase in simulative accuracy, the material properties measured so far are no longer sufficient. For an exact match between simulation and reality, accurate data sets are an essential component - the better the quality of the material data, the more accurate the results.

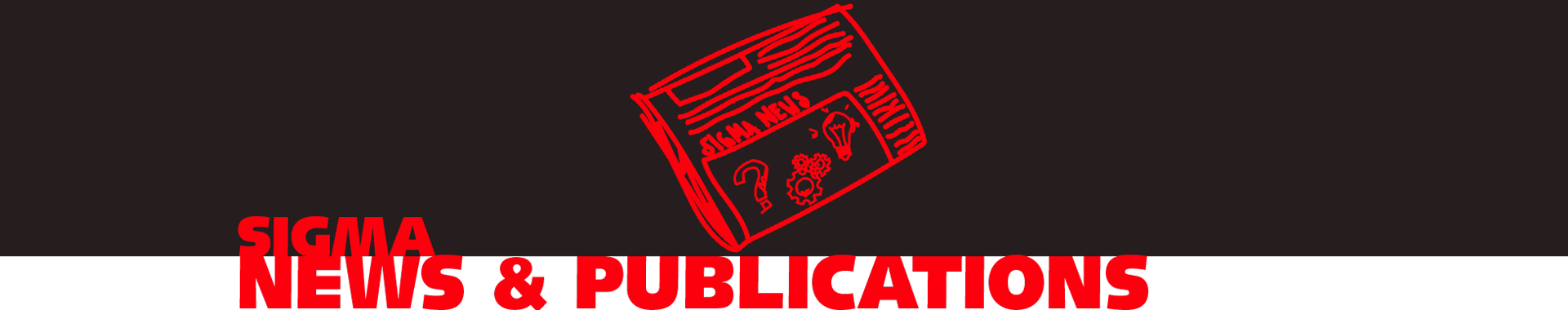

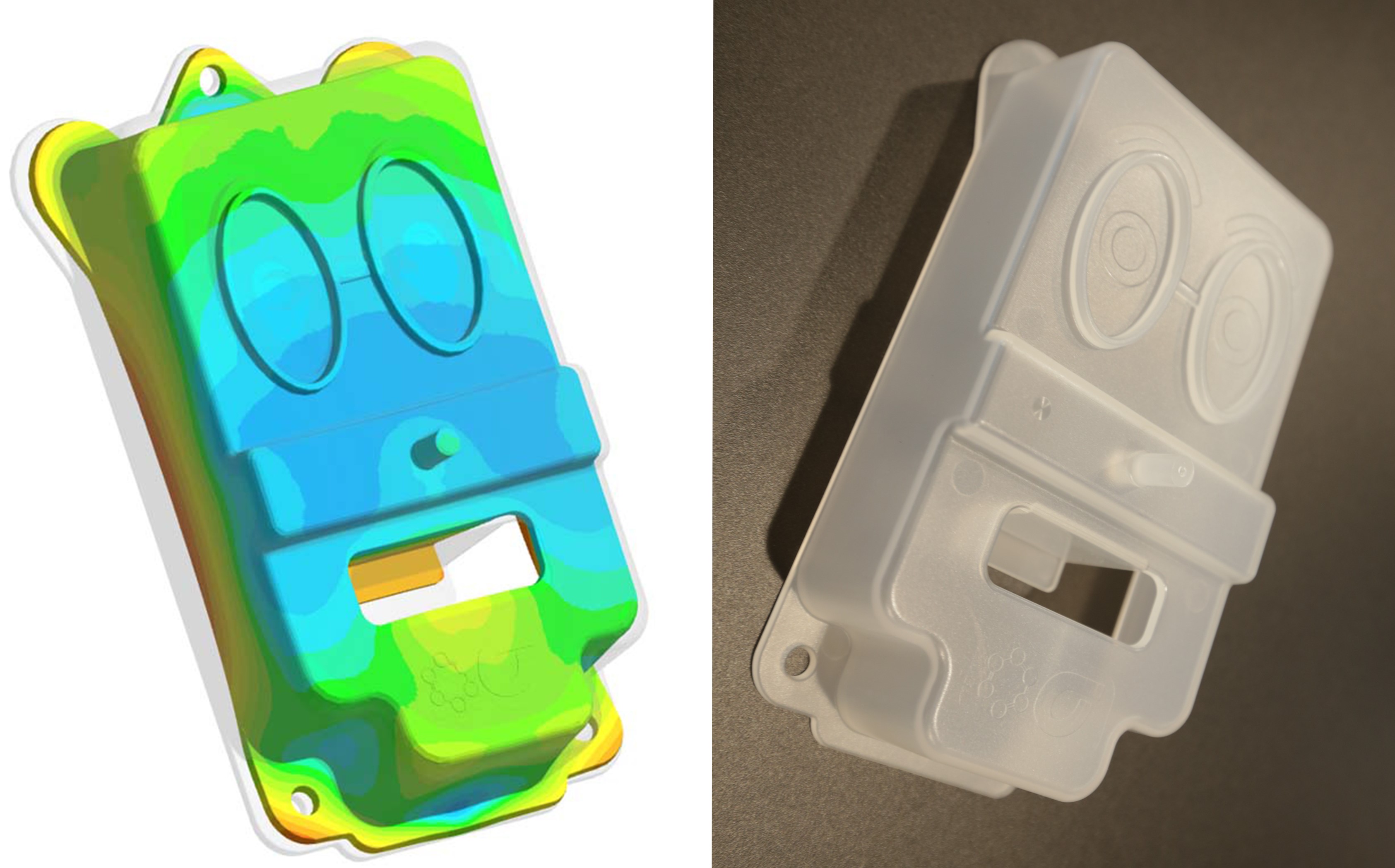

In cooperation with DUFNER.MDT GmbH, SIGMA Engineering has developed a complex test object "Teddy" in order to carry out tests and model validations. This is used to record extensive data (pressures, temperatures, paths, precision and exact dimensions) from the injection molding machine, the injection mold and molded part. This data supplements the existing laboratory measurement values stored in the SIGMASOFT® database for the individual materials. In order to refine the simulation with these previously unrecorded data from reality, the mathematical model approaches had to be extended accordingly. Finite models extrapolate and interpolate results based on the implemented measurement range with a certain margin of error. Through supplementary measurements and the validation of the material parameters, based on concrete processes, this margin of error can now be significantly reduced. In this way, a special and more detailed material database is created with which phenomena such as crystallization or extensional viscosity, which are usually not measured, can also be mapped. For the reliable prediction of shrinkage and warpage, pressure, thermal properties, fiber orientation and mold filling are also considered and compared simultaneously.

"The goal is not just to measure thermoplastics, but to build measurement and validation routines for a virtual behavior of thermoplastics," reports Timo Gebauer, CTO of SIGMA. "The combination of experience and know-how makes it possible to achieve a level of reliability in predicting the behavior of thermoplastics that has never been possible before." This is exactly what makes the difference - with Virtual Molding in combination with the measurement data from the tests in the pilot plant, the full potential of SIGMASOFT® is even more visible since the new version 5.3.1 through verifiable agreement between simulation and reality.